By Hannah Johnson

It has become increasingly common to see meat substitute options in restaurants and grocery stores. Brands producing these options, such as Impossible Burger and Beyond Meat, are becoming commonplace. These alternatives are produced from plant-based proteins and, while providing a good alternative for those with vegetarian and vegan diets, do not completely address the growing need for a meat substitute with a lower negative environmental impact than meat options being manufactured by the animal agriculture industry.

Greenhouse gases are comprised of carbon dioxide, methane, nitrous oxide, or fluorinated gases (e.g., hydrofluorocarbons or sulfur hexafluoride), where human-made emissions largely originate from fossil fuels and agriculture8. Greenhouse gases are capable of trapping heat inside the earth’s atmosphere creating a similar effect to greenhouses, hence the name; however, the current rate of greenhouse gas emissions is unbalanced for the rate of absorption from plants and the oceans, resulting in the increase in earth temperature and climate change we are currently experiencing8. As such, it has been estimated that around 14.5% of the global greenhouse gas emissions are produced by the animal agriculture industry, mostly from cattle1. In an effort to address this concern, lab grown or cultured meats have been proposed.

In June 2023, the U.S. Department of Agriculture (USDA) approved the sale of cultured chicken produced by two California-based companies, Upside Foods and Good Meat2. This approval came about a year after the Food and Drug Administration (FDA) approval on the safe consumption of cultivated chicken produced by these companies1. Though this is a monumental shift for the future of cultured meat in commercial use, it is not the first approval for safe consumption by a food regulator. In fact, the Singapore Food Agency approved the first cultured meat product in December 2020 for cultured chicken bites produced by Eat Just, the parent company of Good Meat7.

Despite the recent approvals for cultured meat, these products have been in development for some time. The first cultured meat was actually produced by Dutch professor Mark Post of Maastricht University using funding from Google’s co-founder4,7. The product was a cultured beef burger that was later cooked and eaten during a press conference in London in August 20131,2,4,7. The publicity from this publicized event led to more funding being given towards companies working on manufacturing cultured meats1,2,4,7. Both Upside Foods and Eat Just are still operating as relatively small manufacturing processes. Due to the small scale of production, the lab grown chicken is only available at select locations. The cultured chicken from Upside Meats can be found at a restaurant in San Francisco called Bar Crenn, while the chicken produced by Eat Just is being sold at one of Chef Jose Andres’ restaurants in Washington D.C.2. Further research and technologies still need to be developed for large scale manufacturing of cultured meats to be sold to the general public. Globally, there are over 150 companies working on developing cultured meats, both at a large scale and to expand production into other meats such as beef, pork, and fish that can be cultured to reduce the need of animal agriculture2.

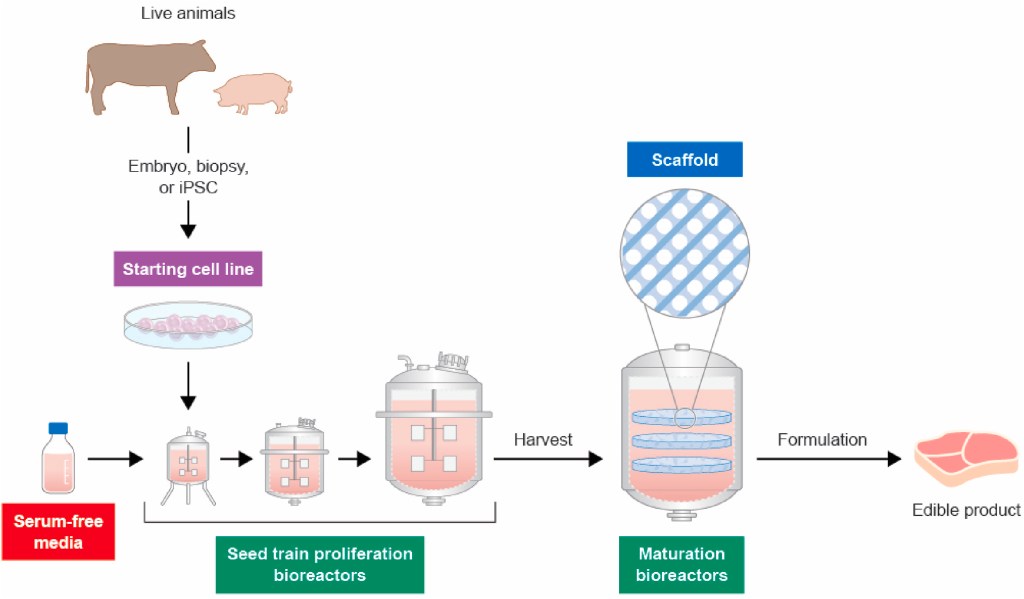

Cultured meat is processed by getting a tissue sample from a young animal or fertilized egg, isolating cells, and growing the cells in a bioreactor with scaffolding before shaping the meat (Figure 2)4,7,1. The process begins with obtaining stem cells capable of proliferating and differentiating into skeletal muscle cells. The optimal type of stem cells such as embryonic stem cells (ESCs), myosatellites (adult stem cells of skeletal muscle), or induced pluripotent stem cells (iPSCs) are still being researched10. Once the cells have been isolated and proliferated, they are placed in a bioreactor to grow on scaffolding. The bioreactor supplies a controlled environment for the proliferating cells by monitoring and adjusting the oxygen and carbon dioxide levels and temperature as well as being able to add growth media10. Inside the bioreactors there will be scaffolding upon which these adherent cells can grow onto and form into tissues10. Once a sufficient volume of cells has formed on the scaffolding, usually in thin sheets, they can be stacked, formed, or shaped through a few different ways, such as 3D printing10. These bioreactors help engineer meats in a way that avoids bacterial contamination from animal waste, the overuse of antibiotics, and artificial growth hormones that are prone to occur in animal agriculture7. Many of the initial materials and techniques used in the cultured meat engineering process were modeled from the biopharmaceutical industry, raising some concern that scaling up production would cause more carbon emissions than the current meat industry 3,4. As the current production capacity of cultured meat is still small, the emission analyses being published are speculations based upon multiple assumptions leading to conflicting results. However, most of the analyses are assuming that the switch to food-grade materials and techniques is expected when scaling-up production, primarily meaning the more stringent purification processes required in biopharmaceuticals4. One study published in January 2023 conducted a life-cycle assessment of the environmental impact potential of cultured meat where they predicted that in 2030 1kg of cultured meat would produce 3-14kg of carbon dioxide emissions4,8. The normal rate for meat production was estimated as 1kg of meat produced releases 100kg of carbon dioxide emissions8. In comparison, the predicted emission rate for cultured meat is much lower and would be a vast improvement in the environmental impact created from meat production.

Lab grown meat has been in development for decades and has recently been approved for consumption by multiple food regulatory agencies. Though only cultivated chicken meat has finished development, been approved, and is being sold, many other types of cultivated meat are still being developed. Current cultured meats are being produced at a small scale; however, work is being done to address the need for large scale manufacturing. In general, scientists are predicting that the potential environmental impact will be lessened with the production of cultured meats in comparison to animal agriculture over the next decade. The first cultivated meat was eaten in 2013. Now in 2023, cultivated meat is capable of being served in restaurants. It will be interesting to see the impact and the growth of these products over the next decade.

TL: DR

- The USDA recently approved the sale of cultured meat in the U.S., where it is now being exclusively sold in restaurants in San Francisco and D.C.

- The potential environmental impact of cultured meat production is predicted to yield much lower greenhouse gas emissions than the current animal agriculture industry.

References

- Thompson, Joanna. “Lab-Grown Meat Approved for Sale: What You Need to Know.” Scientific American, www.scientificamerican.com/article/lab-grown-meat-approved-for-sale-what-you-need-to-know.

- “US Approves Chicken Made From Cultivated Cells, the Nation’s First ‘lab-grown’ Meat.” AP News, 21 June 2023, apnews.com/article/cultivated-meat-lab-grown-cell-based-a88ab8e0241712b501aa191cdbf6b39a.

- Risner, Derrick, et al. “Environmental impacts of cultured meat: A cradle-to-gate life cycle assessment.” bioRxiv (2023): 2023-04.

- “Here’s What We Know About Lab-grown Meat and Climate Change.” MIT Technology Review, 3 July 2023, http://www.technologyreview.com/2023/07/03/1075809/lab-grown-meat-climate-change.

- Chriki, Sghaier, and Jean-François Hocquette. “The myth of cultured meat: a review.” Frontiers in nutrition 7 (2020): 7.

- Boyle, N. “Systems biology and metabolic modeling for cultivated meat: A promising approach for cell culture media optimization and cost reduction.” Comprehensive Reviews in Food Science and Food Safety (2023).

- Sinke, Pelle, et al. “Ex-ante life cycle assessment of commercial-scale cultivated meat production in 2030.” The International Journal of Life Cycle Assessment 28.3 (2023): 234-254.

- “Overview of Greenhouse Gases | US EPA.” US EPA, 23 Dec. 2015, www.epa.gov/ghgemissions/overview-greenhouse-gases.

- Cultured Meat Products | AMSBIO. http://www.amsbio.com/cultured-meat/.

- Chen, Lu, et al. “Large-scale cultured meat production: Trends, challenges and promising biomanufacturing technologies.” Biomaterials 280 (2022): 121274.